Loading...

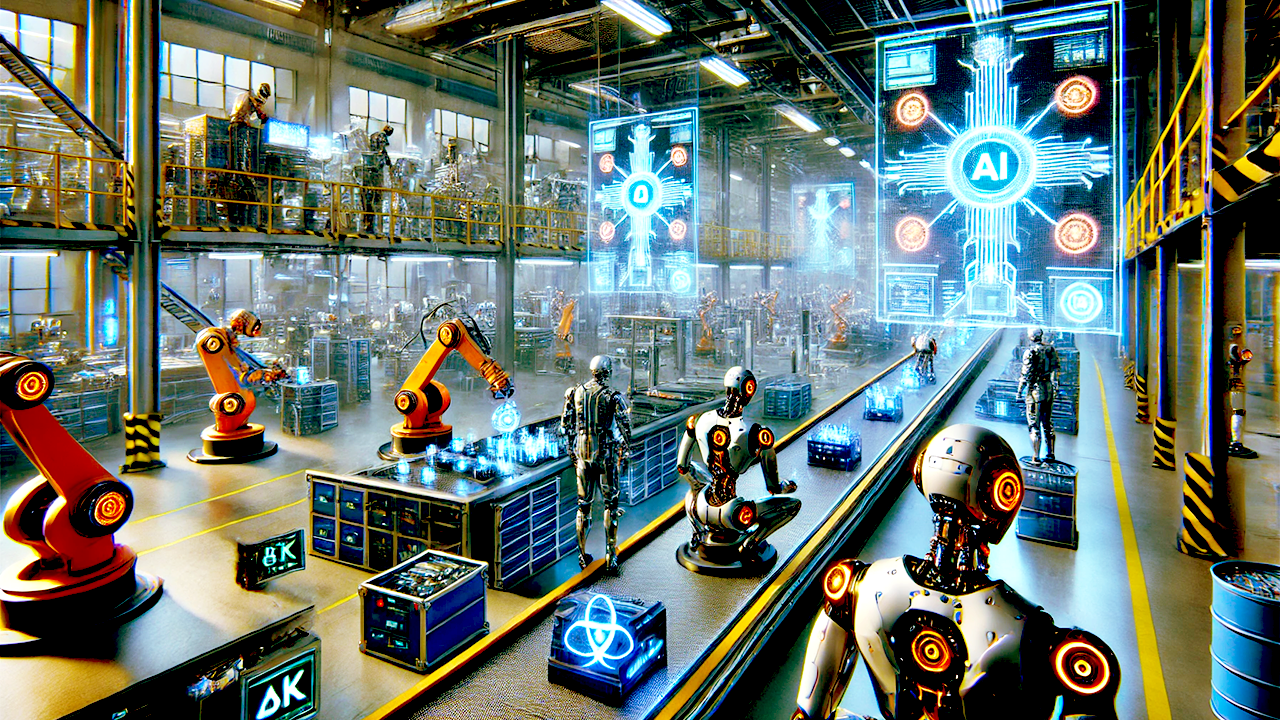

Industrial Robotics 2.0: How AI and Rugged Electronics Are Transforming Factories

Introduction

The factory floor is no longer a realm of clanking machinery and repetitive tasks. Welcome to Industrial Robotics 2.0, where artificial intelligence (AI), rugged electronics, and advanced sensors are driving a seismic shift in manufacturing.

1. From Automation to Autonomy: The Rise of AI-Driven Robots

Traditional industrial robots followed pre-programmed routines. Today, AI unlocks true autonomy through:

Key Innovations

- Reinforcement Learning (RL): Robots refine tasks through trial and error

- Generative AI: Optimizes workflows by simulating millions of scenarios

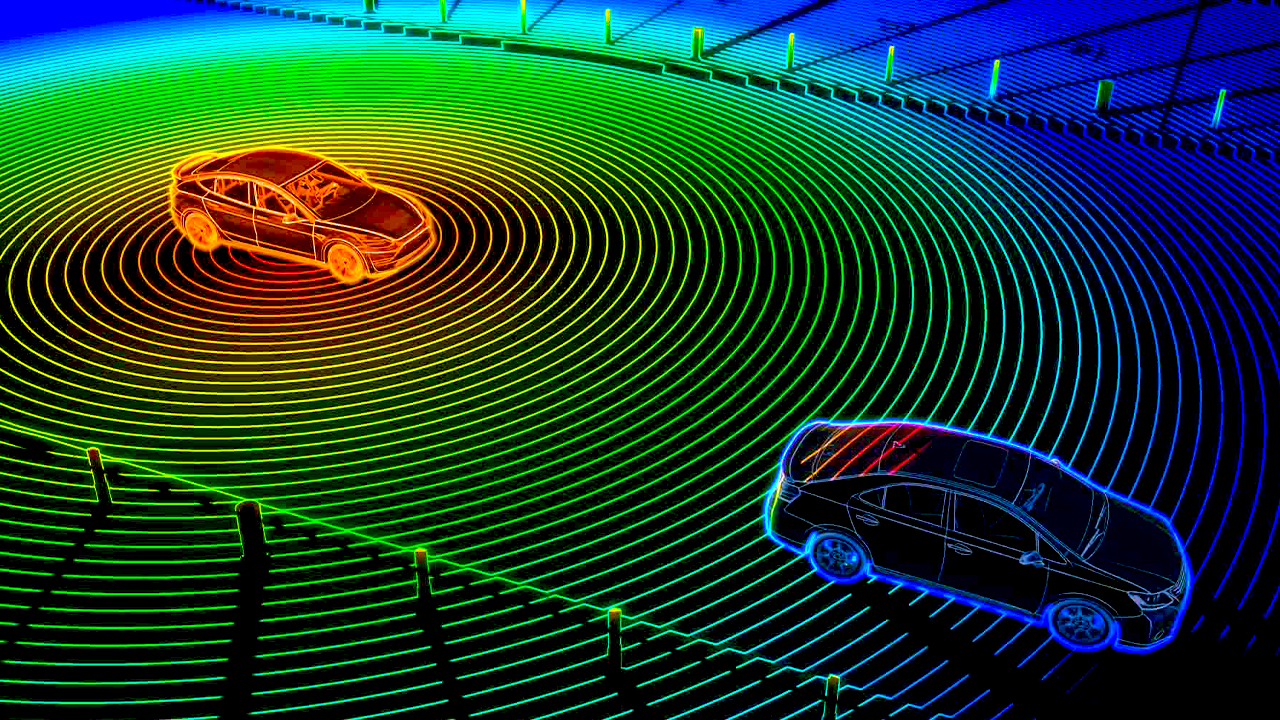

- Multimodal Perception: LiDAR sensors enable dynamic environment navigation

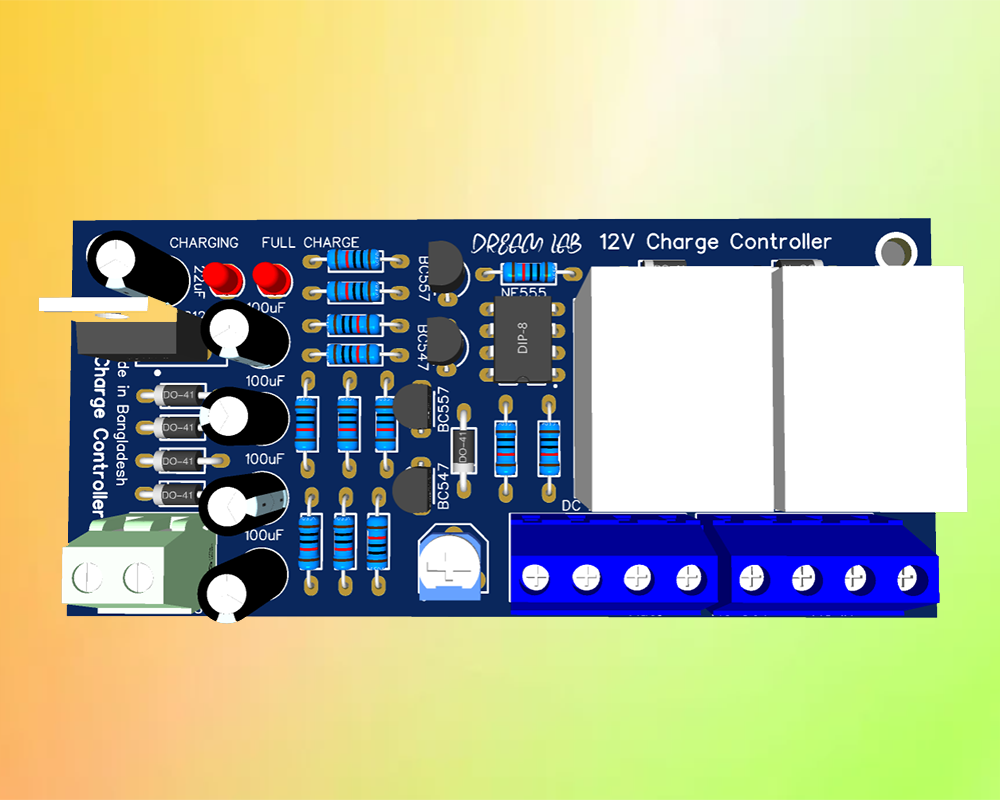

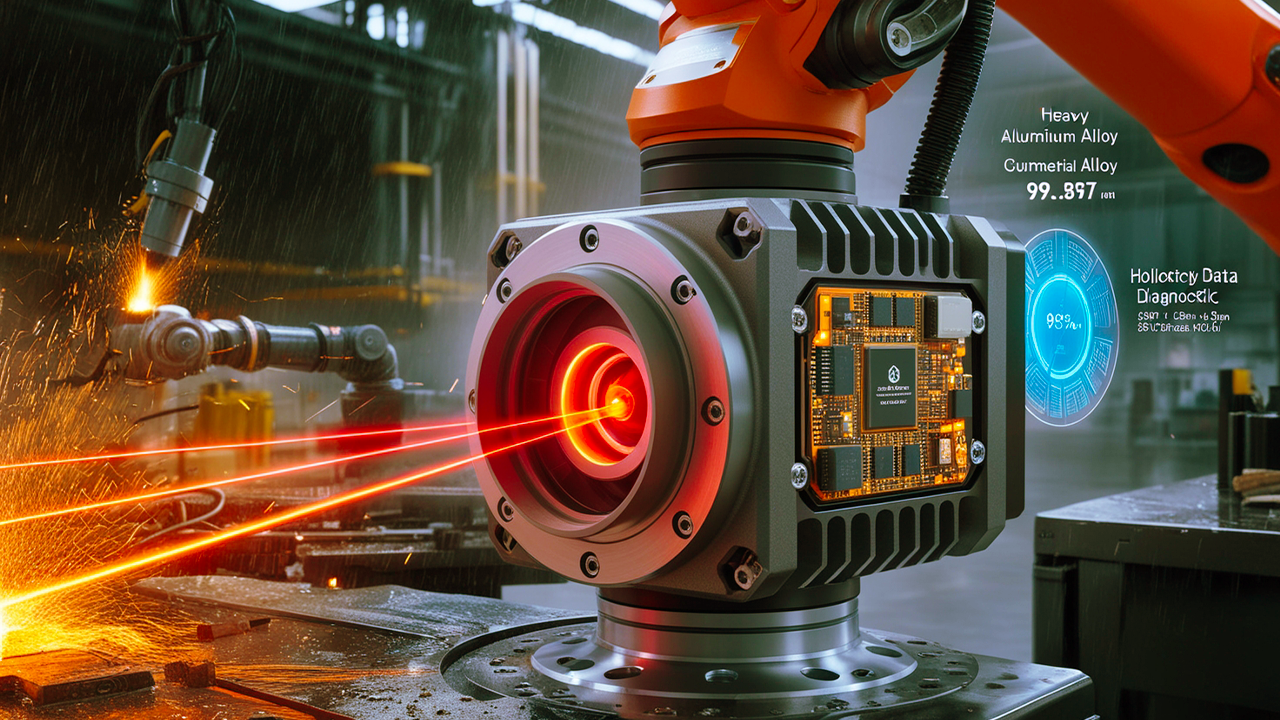

2. Rugged Electronics: The Backbone of Industrial Robotics 2.0

Cutting-Edge Components

- Digital LiDAR: 1080P HD 3D perception with 600m range

- Force Sensors: Enable stable movement on uneven surfaces

- Domain Controllers: Local data processing without cloud dependency

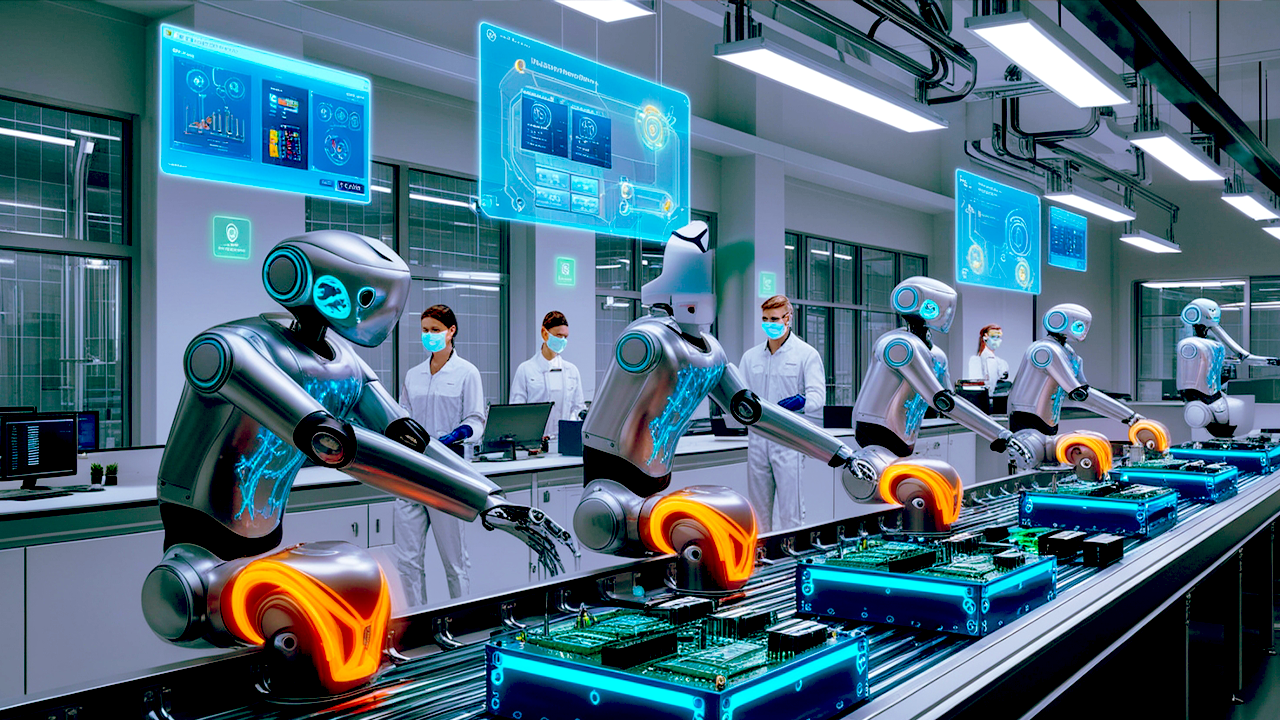

3. Human-Machine Collaboration: The Dawn of Industry 5.0

Industry 5.0 emphasizes synergy between humans and robots:

Cobots in Action

- Force-limiting joints for safe interaction

- AI-powered exoskeletons for heavy lifting

4. Sustainability and the Circular Economy

- AI algorithms minimize power consumption

- Robotic disassembly lines reduce e-waste by 40%

5. Overcoming Challenges

| Challenge | Solution |

|---|---|

| Workforce Transition | AI-augmented training programs |

| Cybersecurity | Blockchain-protected networks |

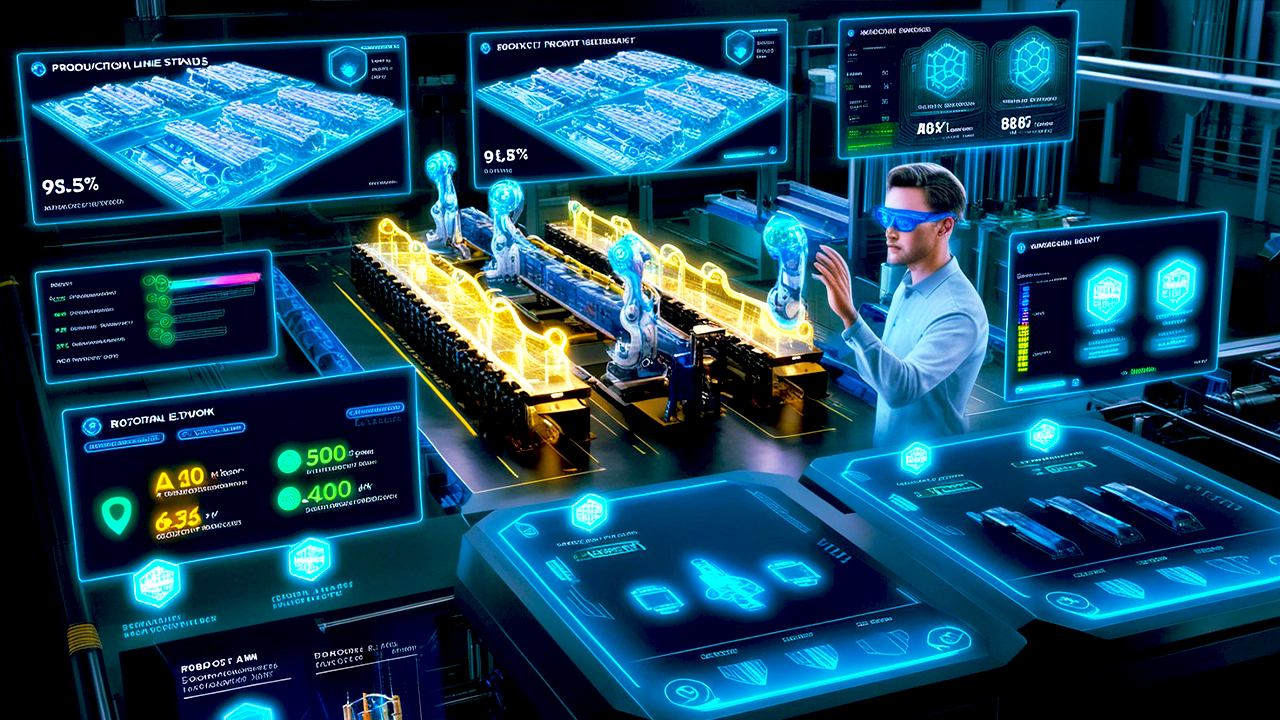

6. The Future: AI Agents and Decentralized Robotics

By 2030: Autonomous AI agents managing entire production lines

Conclusion

Industrial Robotics 2.0 merges AI, rugged electronics, and sustainability to create agile, human-centric factories. As demonstrated by recent innovations, the future of manufacturing is intelligent and adaptive.